SRi founded in Marseille, France, in 1978 has a decades long history of serving the oil and gas, power, refining, chemical and, metals and mining industries. SRi started in France by supplying and servicing local refineries.

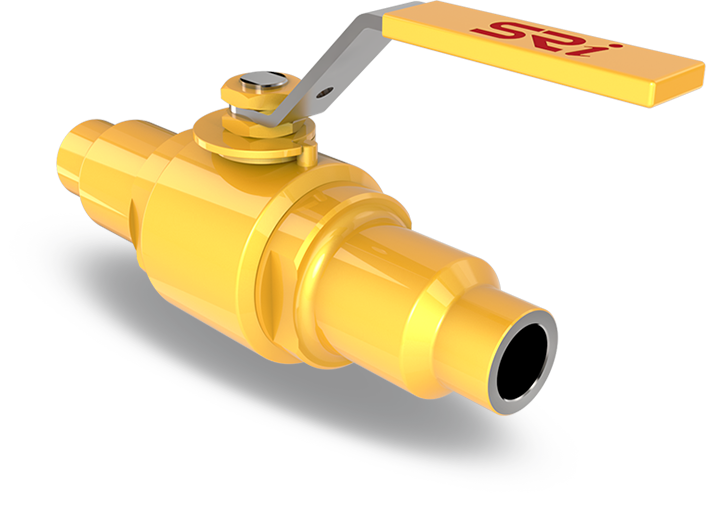

In 1990 SRi decided to expand into the Machining of trunnion and floating ball isolation valves to its own proprietary custom design. These designs are based on its experience in servicing the oil and gas, and refining industries.

SRi broadened its product line of isolation valves by purchasing VANNES RIGAU in 2005.

SRi now has a full line of isolation valves: gate, globe, check and ball.

Over 80% of SRi’s sales are now exported to markets outside of France primarily to companies in Europe, Africa and Asia.

SRi is a qualified supplier for worldwide and national companies including end-users and EPC contractors.

The high demand for SRi’s quality valves both custom designed and standard has caused

SRi to increase its capacity by building a new facility in its headquarters city of Marseille, France.

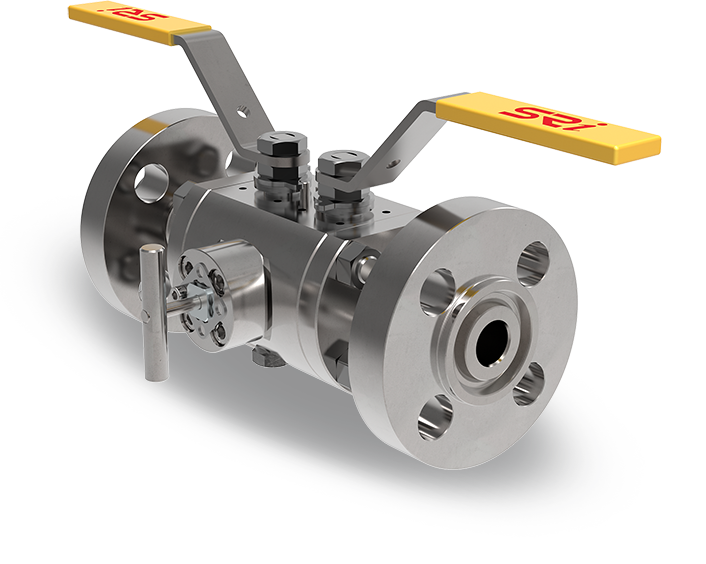

SRi Trunnion API 6D/6A Products

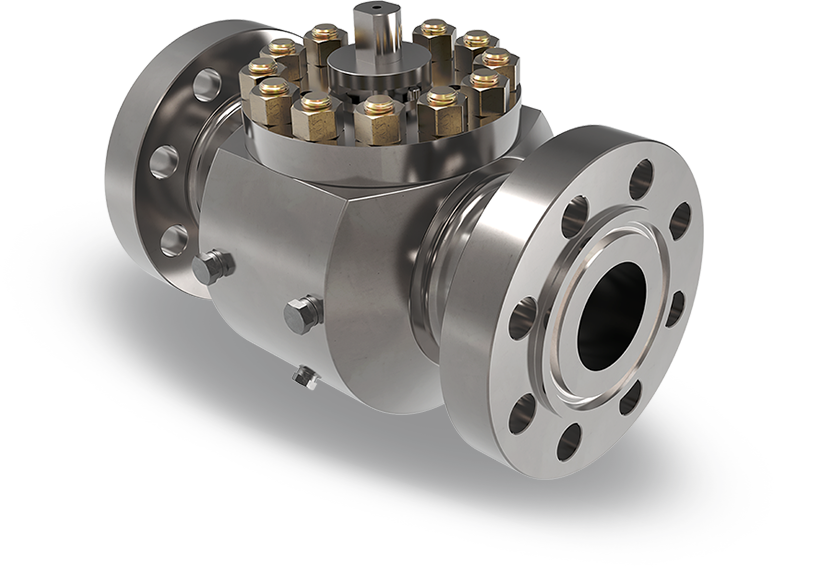

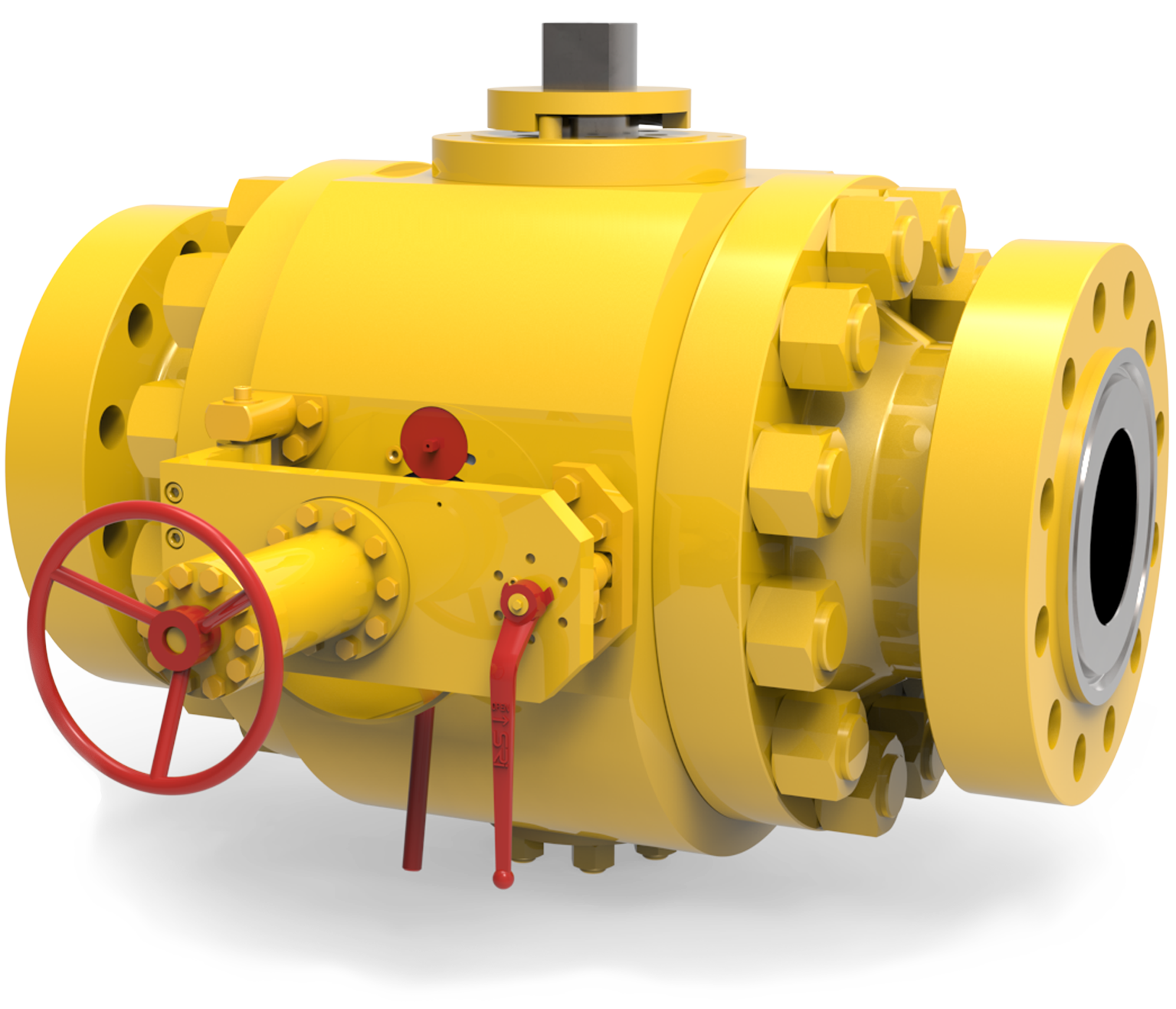

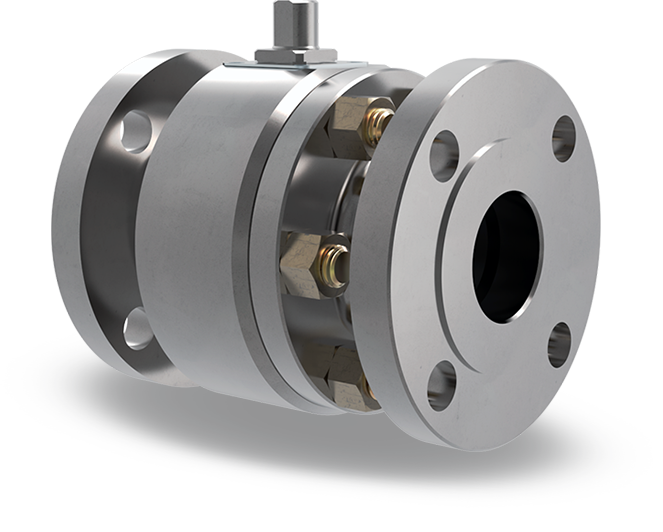

Side-Entry

Side-Entry

The side-entry ball valve is the most common and popular design.

Given its great modularity, SRi can manufacture any side-entry ball valves with special options.

In case of maintenance operation, all parts of the valve can be replaced, so valve lifetime is extended.

Range

ND 1/2" (DN15) to ND 36" (DN900)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

API 3000 to 10000

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Lifting lugs /valve support

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

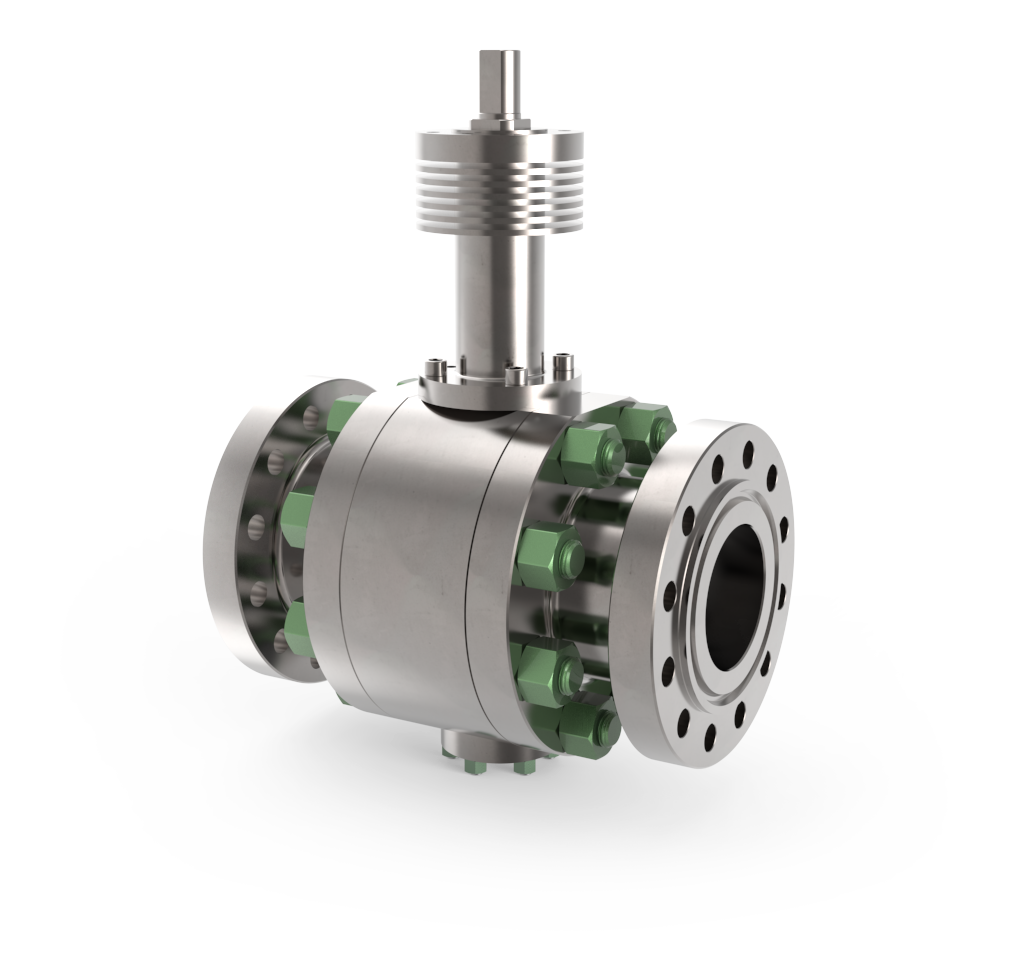

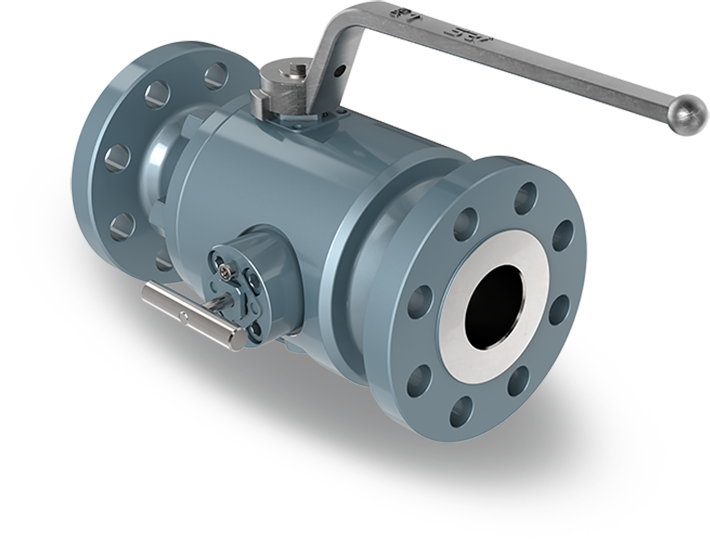

Top-Entry

Top-Entry

The cover of top-entry ball valve can be disassembled from the body of the valve, so all parts can be easily maintained or replaced in-line.

On demand, trem, trunnion and ball can be made as a monobloc piece. This option increases the reliability of the valve.

This construction allows more flexibility in customization of driving train design,

allowing for example the mounting of an actuator directly on the bonnet without an intermediary bracket.

Range

ND 1" (DN25) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Lifting lugs /valve support

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Engineering & Technologies

SRi uses the latest techniques like CAD, DAO and structural calculations in the conception, verification,

analysis and testing of our products.

A permanent research and development program leading to patents means always more reliability and performance in our products.

SRi is equipped with a finite element analysis software ANSYS.

This software can simulate: Thermal, solid mechanics, mechanics of fluid, fluid/structure interaction.

Other Trunnion Products

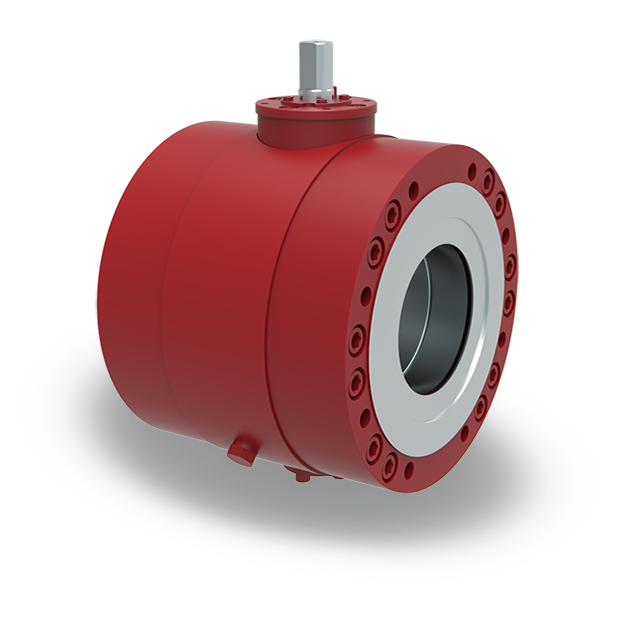

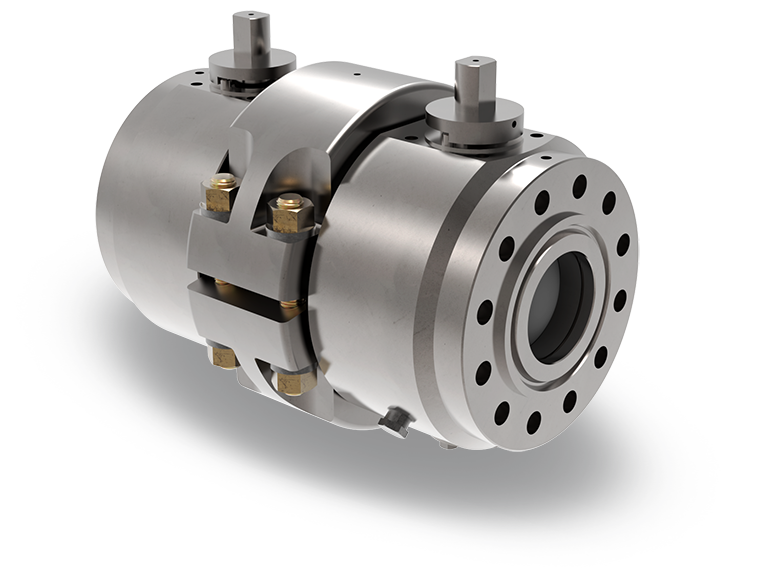

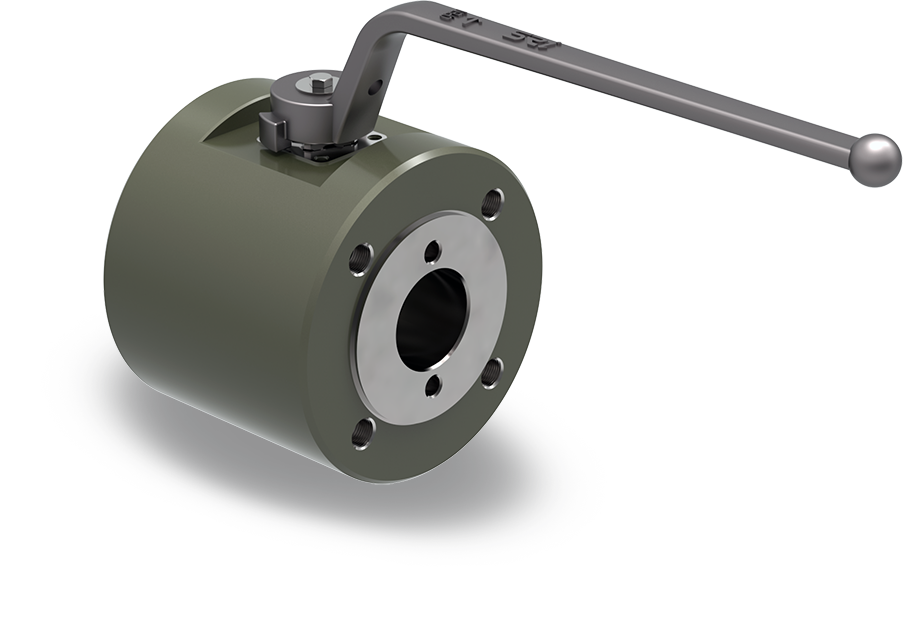

Wafer

Wafer

- Wafer ball valve saves space and weight, thanks to the absence of flange.

- This design also allows replacement of a gate valve without modification of the piping should a reduced bore be considered

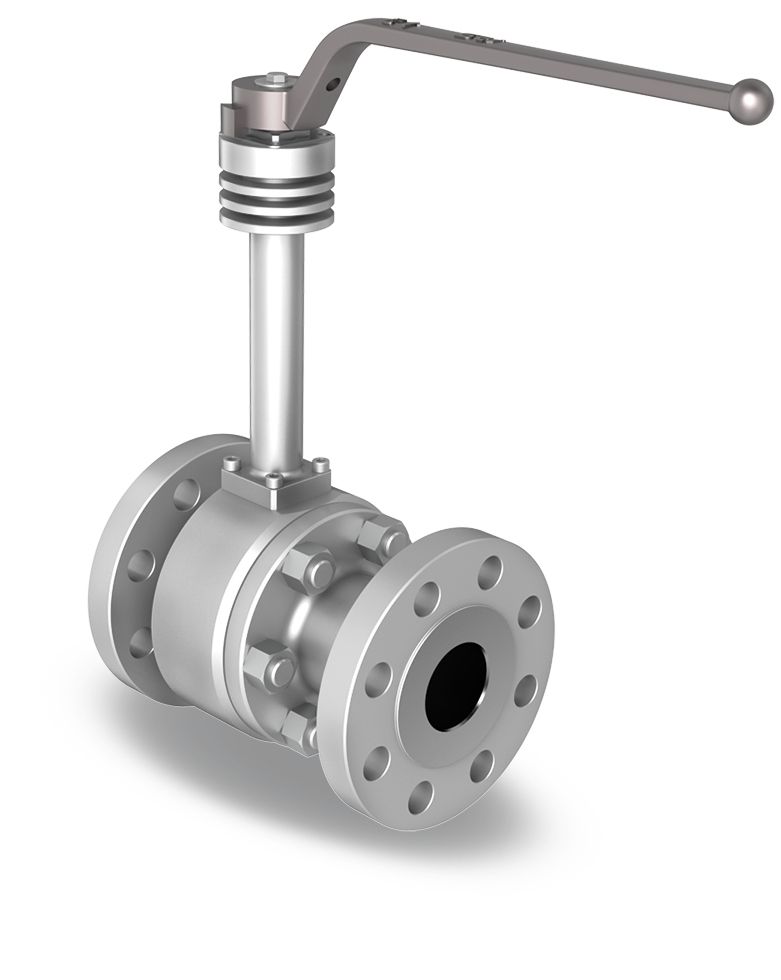

Cryogenic

Cryogenic

When the expected service or design temperature is out of the standard temperature range of SRi ball valve,

SRi manufactures high temperature or cryogenic ball valves

The minimum temperature of cryogenic ball valve is -196°C.

The maximum temperature of high temperature ball valve is +450°C for TCC (Tungsten Carbide Coating) and +650°C for CCC (Chromium Carbine Coating).

Wafer

Range

ND 1" (DN25) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Lifting lugs /valve support

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Cryogenic

Range

ND 1/2" (DN15) to ND 36" (DN900

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Thermic extension

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

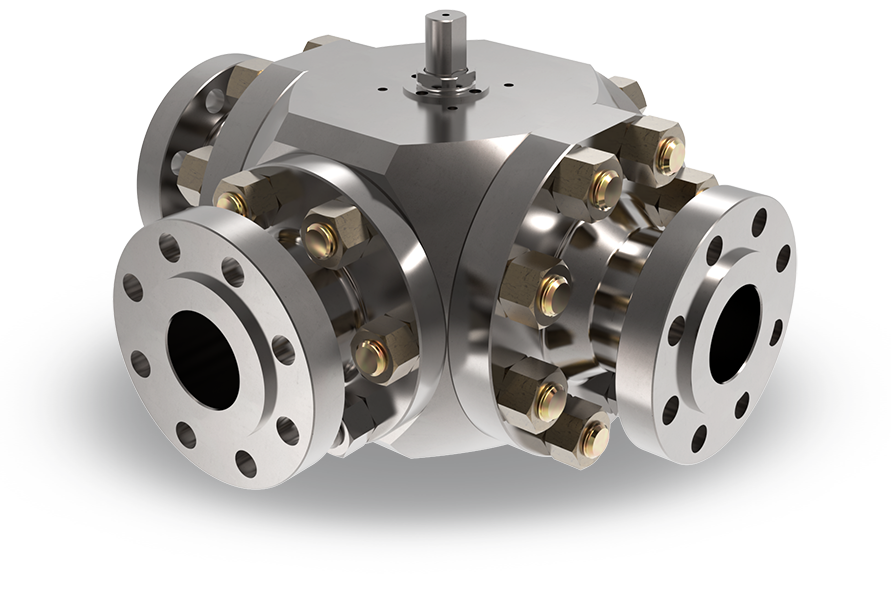

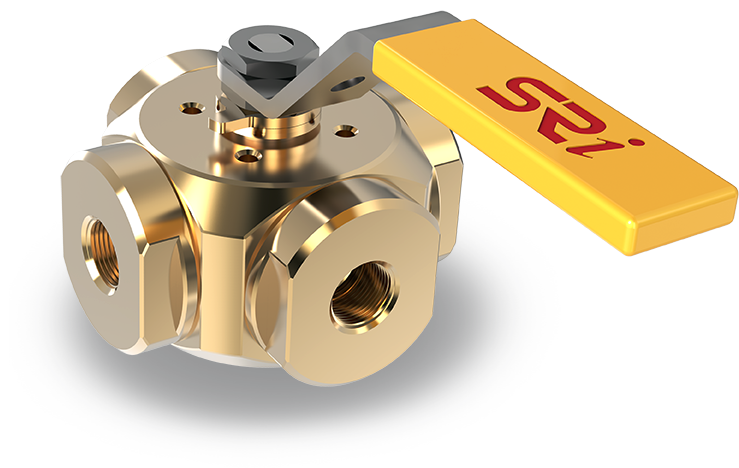

Multiways

Multiways

SRi multiways ball valve can be made, on demand, with L-port, T-port or X-port. Ball valve can be designed as transflow or non-transflow.

The non-transflow avoids connection of 3 or 4 branches during stroke.

The SRi multiways ball valve keeps the valve tight even if the automatic cavity relief by seat leakage is actived.

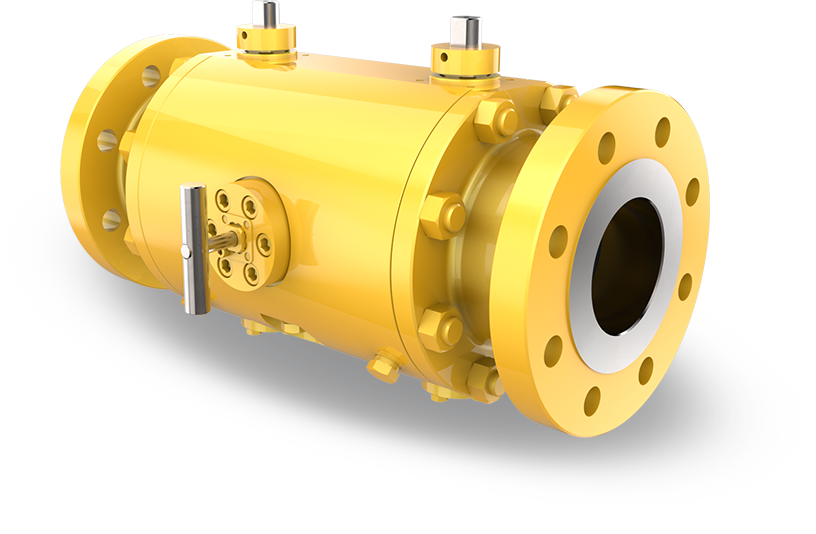

Pig Launcher

Pig Launcher

SRi pig launcher (or receiver) is safe and much more compact than a pig trap.

Manual or automatic secured access door.

The pig launcher can be equipped with an optional by-pass to allow flow between both sides of the valve if the pig is presented in the valve ball.

Multiways

Range

ND 1" (DN25) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Pig Launcher

Range

ND 1/2" (DN15) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Lifting lugs /valve support

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

DBB

DBB

Double Block and Bleed (DBB) ball valve is made of two balls in one valve body.

A bleeder is added between the two balls of the valve.

This system is equivalent to a Double Isolation Bleed (DIB) single ball valve.

Tandem Ball Valve

Tandem Ball Valve

SRi tandem ball valve is constituted by two balls, like the Double Block and Bleed ball valve,

but the face-to-face dimension is in accordance with ASME B16.10.

On site, a SRi tandem ball valve can replace a single ball valve without modification of the pipe meaning two ball valves instead of only one.

DBB

Range

ND 3/4" (DN20) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Needle plug

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Tandem

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Lifting lugs /valve support

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Quality & Certification

SRi applies the whole cycle of management, conception, production and trading in conformance with ISO prescriptions. SRi is certified ISO 9001, ISO 14001, ISO 45001 and licensed API 6A and API 6D.

The quality system applied is in conformity with the referring dispositions to European Pressure Equipment Directive 2014/68/EU and

European Directive ATEX 2014/34/EU. Starting up instructions following PRBE026F

Please click on logo to show.

SRi Floating Ball Valves

Side-Entry

Side-Entry

Two parts body cast or forged steels.

Soft or metal seats.

Design & Machining by SRi.

All valves tested after assembly.

All part can be identified and replaced by valve serial number.

Side-Entry

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Drain plug

Stem injection fitting

Other Floating Ball Valves

SBB/DBB

SBB/DBB

Double Block and Bleed (DBB) ball valve is made of two balls in one valve body.

A bleeder is added between the two balls of the valve.

This system is equivalent to a Double Isolation Bleed (DIB) single ball valve.

Cryogenic

Cryogenic

When the expected service or design temperature is out of the standard temperature range of SRi ball valve,

SRi manufactures high temperature or cryogenic ball valves.

The minimum temperature of cryogenic ball valve is -196°C.

The maximum temperature of high temperature ball valve is +450°C for TCC (Tungsten Carbide Coating) and +650°C for CCC (Chromium Carbine Coating).

SBB / DBB

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Stem injection fitting

Cryogenic

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Stem injection fitting

Multiways

Wafer

Wafer

Wafer floating ball valve saves space and weight, thanks to the absence of flange.

Multiways

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Stem injection fitting

Wafer

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Stem injection fitting

Manufacturing

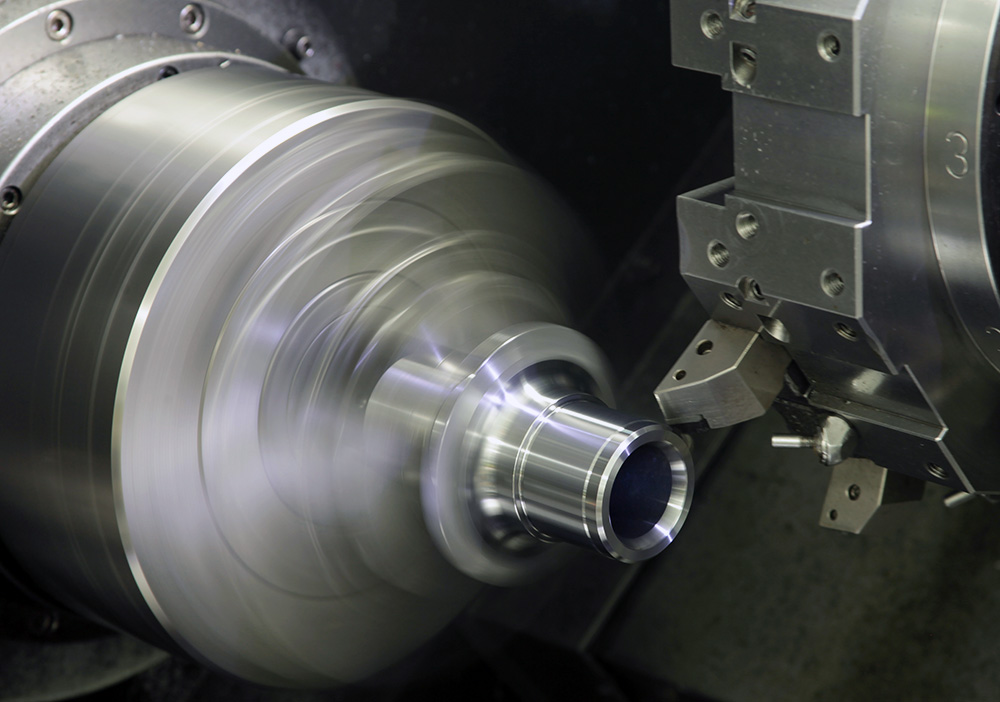

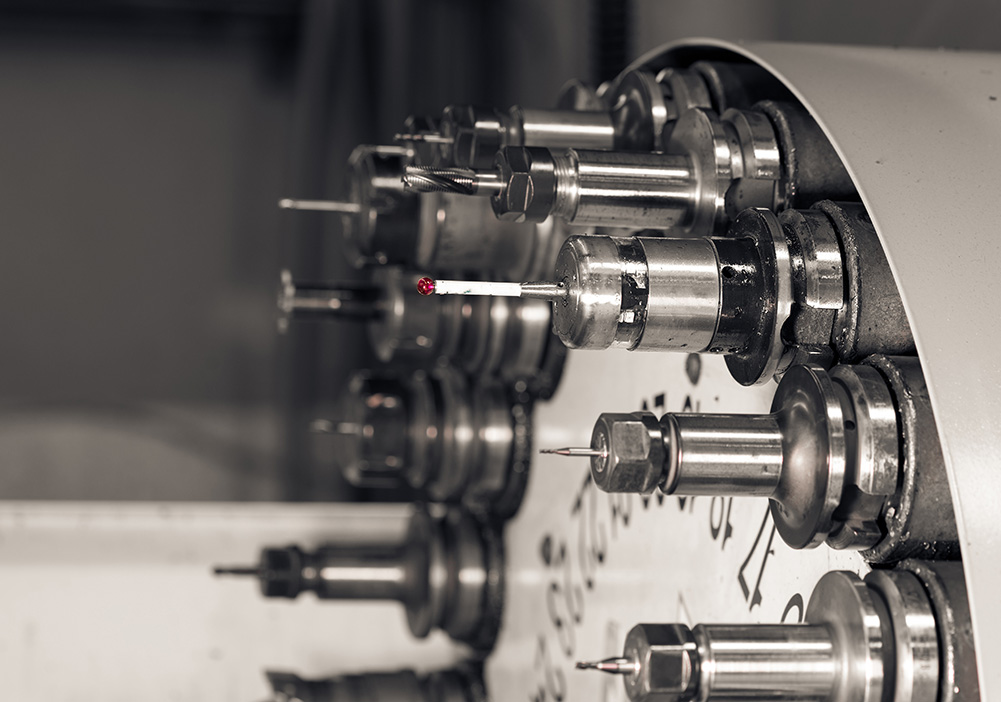

SRi has a workshop equiped with a full complement of CNC and machining equipment,

benefical to the quality and fast delivery of our products.

SRi machining capabilities is always evolving in order to increase our abilities.

All the raw materials used for the machining come from European industry.

Our goal is to manufacture the best quality possible in all our products.

Threaded High Pressure Ball valves

Threaded Side Entry

Threaded Side Entry

Valves are designed to work with the full differential pressure of their class, whatever the DN.

Multiways

Multiways

SRi multiways floating ball valve can be made with L-port or X-port.

Threaded side entry

Range

ND 1/2ˮ (DN15) to ND 1ˮ1/2 (DN40)

Classes

ASME CLASS 800 to 2500

DIN-PN PN * to *

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

ENP on seat/ball/stem/body

Extended stem

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Optional Design features

ENP on seat/ball/stem/body

Extended stem

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Multiways

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

Bleed valve

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Lifting lugs /valve support

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Bolted High Pressure Ball valves

Bolted Side Entry

Bolted Side Entry

The body and flanges valves are homogeneous with the Pressure/Temperature relations (PN) of each pressure class.

DBB

DBB

Double Block and Bleed (DBB) ball valve is made of two balls in one valve body.

A bleeder is added between the two balls of the valve.

Bolted side entry

Range

ND 1/2ˮ (DN15) to ND 6ˮ (DN150)

Classes

ASME CLASS 150 to 600

DIN-PN PN 10 to 40

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Connection ends upon request

Firesafe design

O-ring seals

Soft seat insert

Solid ball

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on all wetted parts

Polymeric lip-seals

Drain plug

Stem injection fitting

DBB

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

Bleed valve

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Lifting lugs /valve support

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

Three parts

Three parts

This is a three parts, cast and bolted valve. The basic construction has been improved in order to minimize the quantity and variety of parts.

The operating devices (ISO base plate, stem, packing gland and stopping plate) are the same as that of side entry floating valves,

which reduces the quantity of spare parts in stock and allows accessories to be interchangeable.

Range

ND 1/2" (DN15) to ND 36" (DN900)

Classes

ASME CLASS 150 to 2500

DIN-PN PN 10 to 64

API 3000 to 10000

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

API 6D/6A design & construction

API 6D & ASME B1610 face to face

Antistatic device

Double block and bleed (DBB)

Drain plug

Connection ends upon request

Firesafe design

O-ring seals

Self-Relieving seat

Soft seat insert

Trunnion mounted

Lifting lugs /valve support

Vent plug

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Automatic bleeding system

By-pass system

Double Piston Effect (DPE)

Double Isolation & Bleed (DIB)

ENP on seat/ball/stem/body

Extended stem

Heating jacket

Locking device

Metal to metal seats

Overlay on seat pocket

Overlay on dynamic seal pockets

Overlay on all wetted parts

Polymeric lip-seals

Single Piston Effect

Stem injection fitting

Seat injection fitting

Transition pups pieces BW ends

-->

-->